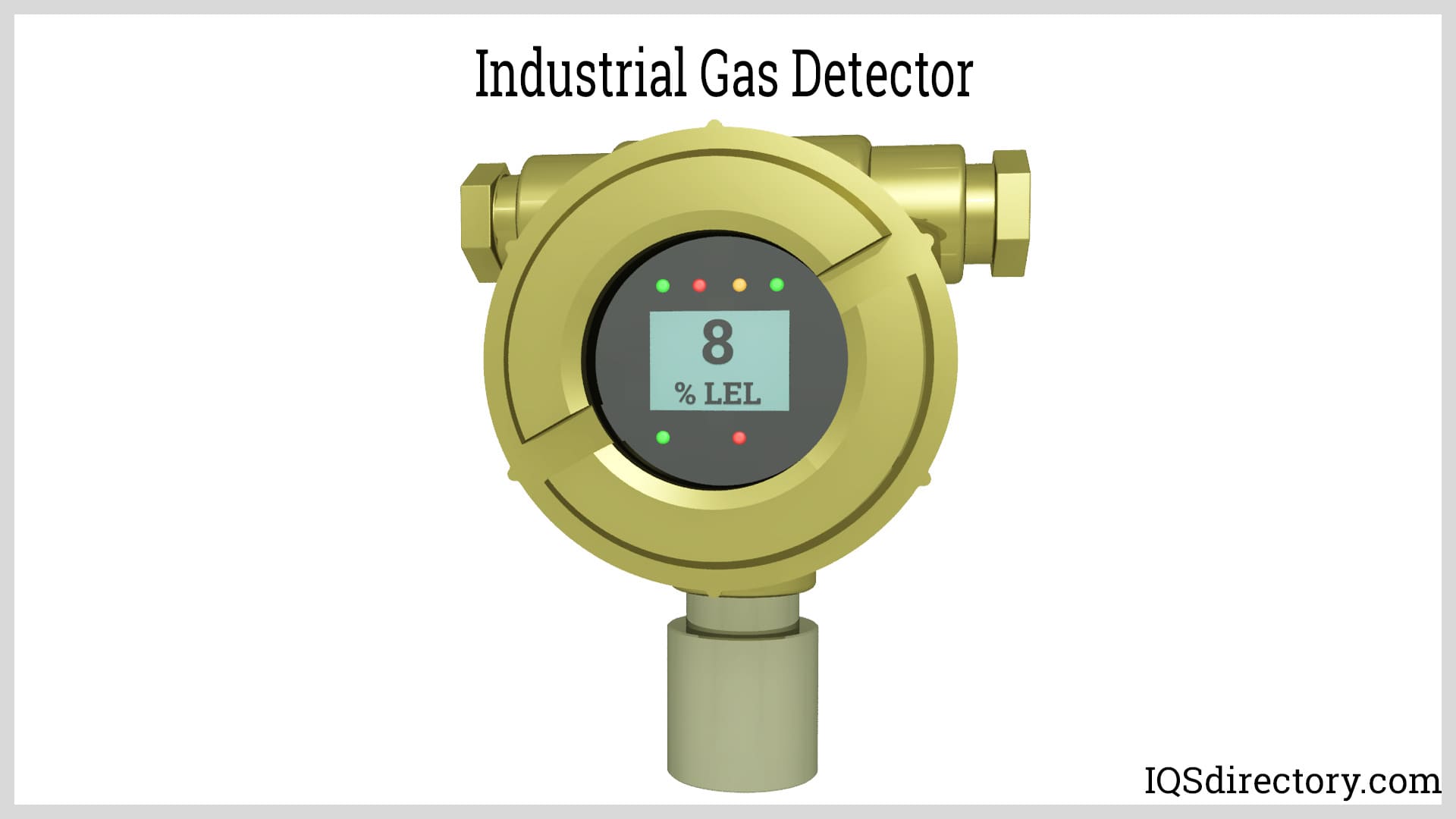

Ultrasonic leak detectors produce high-frequency, powerful pulses that travel through materials as waves. When there is a surface defect or interruption, some energy is reflected back instead of traveling through materials. To find a leak, ultrasonic leak detection locates high-frequency sounds of leaking pressurized gas. If the leak is turbulent, the leak detector only needs to discover compressed air. Read More…

DOD Technologies is committed to providing great service and customer care. From inquiry to delivery, our highly skilled team provides exceptional support and accountability to our customers. We offer Service Contracts, Calibration Services, Start Up Services, Field Service & Training and Installation & Design.

SERV-I-QUIP specializes in gas leak detectors, including helium leak detectors and halogen sniffer for air conditioning and refrigeration manufacturers. We also offer the leak test gas recycle system plus the proof, leak, flow test system. See us for your HVAC/R and appliance process equipment.

Vacuum Technology provides a variety of leak testing products including helium and refrigerant leak detectors. Our leak detectors offer quality of the highest industry standards for reliability and serviceability. We will custom design a leak detection system for you, so call us today!

ENMET, LLC is committed to providing gas detection solutions with quality products and services that conform to customer requirements. ENMET specializes in medical air, environmental and industrial health and safety monitoring instruments for a variety of hazardous gas conditions. ENMET’s focus is to provide innovative solutions utilizing sound engineering and quality manufacturing practices...

More Ultrasonic Leak Detector Manufacturers

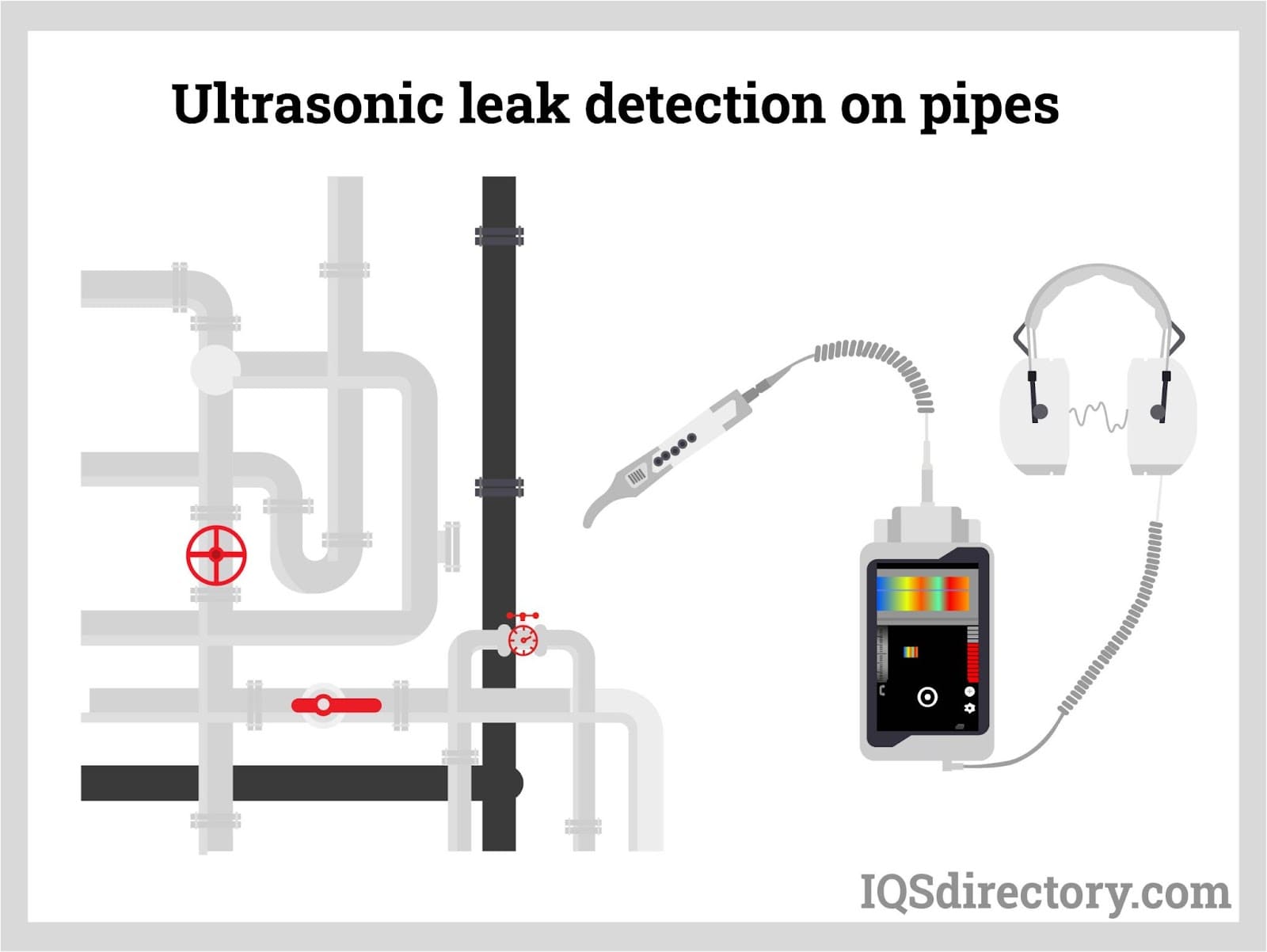

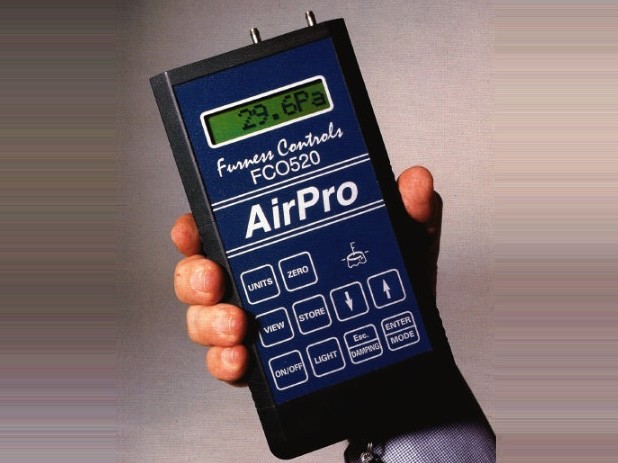

An ultrasonic detector is effective if it converts high-frequency leak sounds to lower ranges – a process called heterodyning. Hissing leaks can be located by listening through a pair of headphones. Every turbulent gas will produce ultrasound when it leaks. Ultrasonic detectors can even pick up air rushing into a system while being vacuumed.

Ultrasonic Maintenance Examples

Ultrasonic maintenance works for lots of equipment. Vacuum leak detection, gas leak detection, and compressed air leak detection are common applications of ultrasonic technology.

- Inspection of complicated air and gas pipe networks: Compressed air and compressed gasses are necessary for facilities to function. An intricate network of pipelines distributes these gasses from a central point. Leaks can happen anywhere, causing expensive repairs. Ultrasonic leak detection is the quickest, most precise method for finding even the smallest leak in a system.

- Safety enhancements: The main problem caused by compressed air leaks is efficiency loss. However, safety takes precedence when a system is leaking harmful or dangerous gases. Leaks can place staff in immediate danger, so leaks must be rapidly located and fixed.

Advantages of Ultrasonic Leak Detection

- Reliable air and gas delivery: Leaky systems use more energy to keep the pressure at the same level. If there are enough leaks, the system won't function properly. This could lead to a chain reaction of inefficiencies in compressed gas-dependent end-use processes or the termination of those operations.

- Improved safety: All working staff are significantly at risk from hazardous gas leaks. Ultrasonic leak detection allows companies to comply with safety standards.

- Low maintenance costs: By spotting leaks as soon as they appear, repairs can be planned for a time that won't interfere with output. Massive failures requiring involved, and expensive repairs are minimized or completely avoided.

Drawbacks of Ultrasonic Leak Detection

Ultrasonic equipment can rarely be automated, allow users to test to a leak rate standard, provide repeatable accuracy, or offer test result management.

There are leak detection techniques that offer more precise and controlled leak testing. The typical ultrasonic leak detection device can only identify leaks in the 60 sscm range. The operator’s performance, environmental context, and capacity to separate sound frequency from background noise all affect the efficiency of ultrasonic leak detection. It’s harder to identify leaks when acoustical leak testing is carried out on insulated lines, underground, or through walls.

Choosing the Correct Ultrasonic Leak Detector Manufacturer

To ensure you have the most positive outcome when purchasing ultrasonic leak detectors from an ultrasonic leak detector manufacturer, it is important to compare several companies using our directory of ultrasonic leak detector manufacturers. Each ultrasonic leak detector manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each ultrasonic leak detector business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple ultrasonic leak detector businesses with the same form.

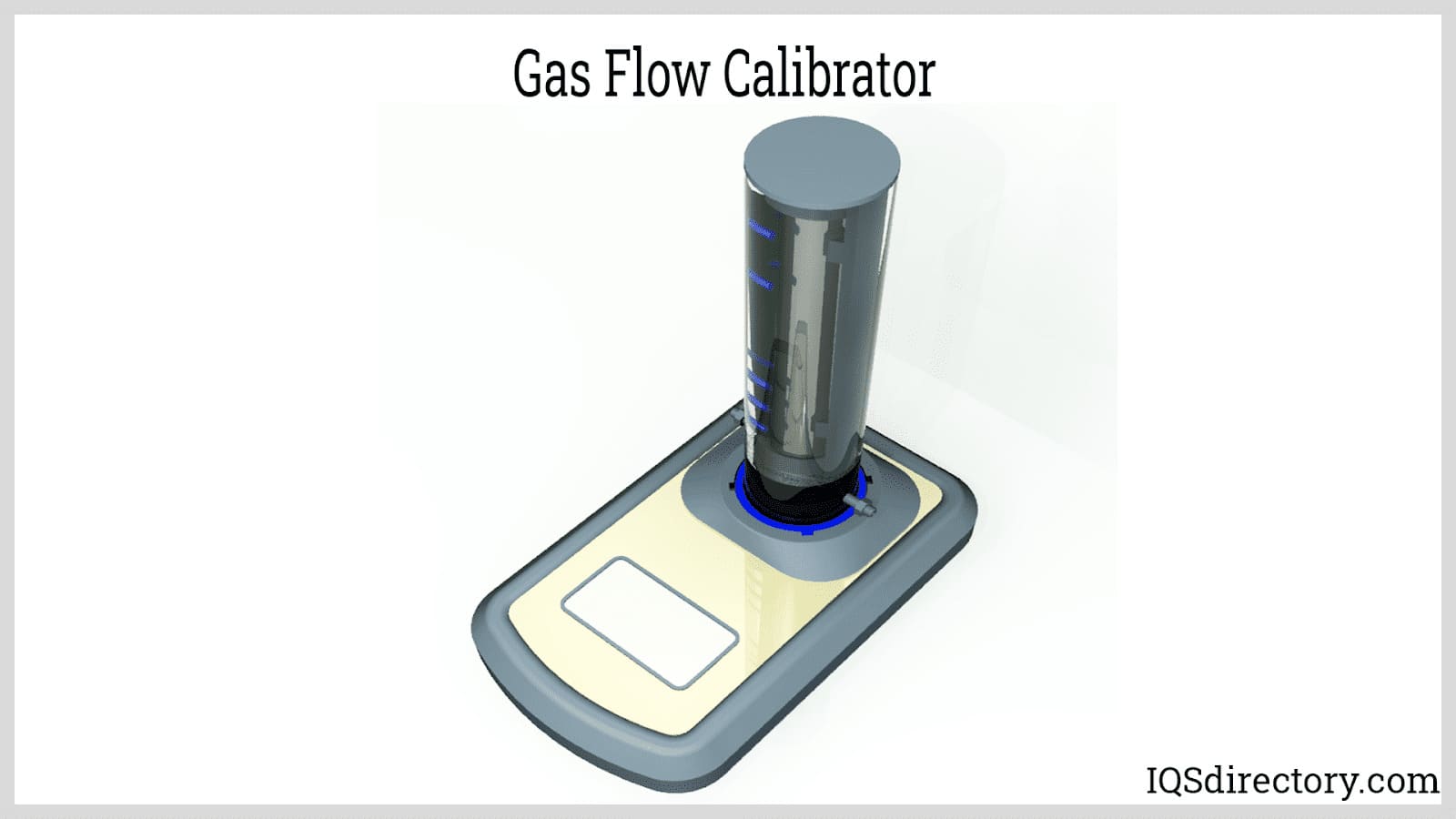

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services