It is important to identify refrigerant gas leaks as they can increase ozone depletion and, in large amounts, cause heart problems when inhaled by humans. Refrigerant gases are commonly used in industrial and commercial coolant systems. Read More…

DOD Technologies is committed to providing great service and customer care. From inquiry to delivery, our highly skilled team provides exceptional support and accountability to our customers. We offer Service Contracts, Calibration Services, Start Up Services, Field Service & Training and Installation & Design.

SERV-I-QUIP specializes in gas leak detectors, including helium leak detectors and halogen sniffer for air conditioning and refrigeration manufacturers. We also offer the leak test gas recycle system plus the proof, leak, flow test system. See us for your HVAC/R and appliance process equipment.

Vacuum Technology provides a variety of leak testing products including helium and refrigerant leak detectors. Our leak detectors offer quality of the highest industry standards for reliability and serviceability. We will custom design a leak detection system for you, so call us today!

ENMET, LLC is committed to providing gas detection solutions with quality products and services that conform to customer requirements. ENMET specializes in medical air, environmental and industrial health and safety monitoring instruments for a variety of hazardous gas conditions. ENMET’s focus is to provide innovative solutions utilizing sound engineering and quality manufacturing practices...

More Electronic Leak Detector Manufacturers

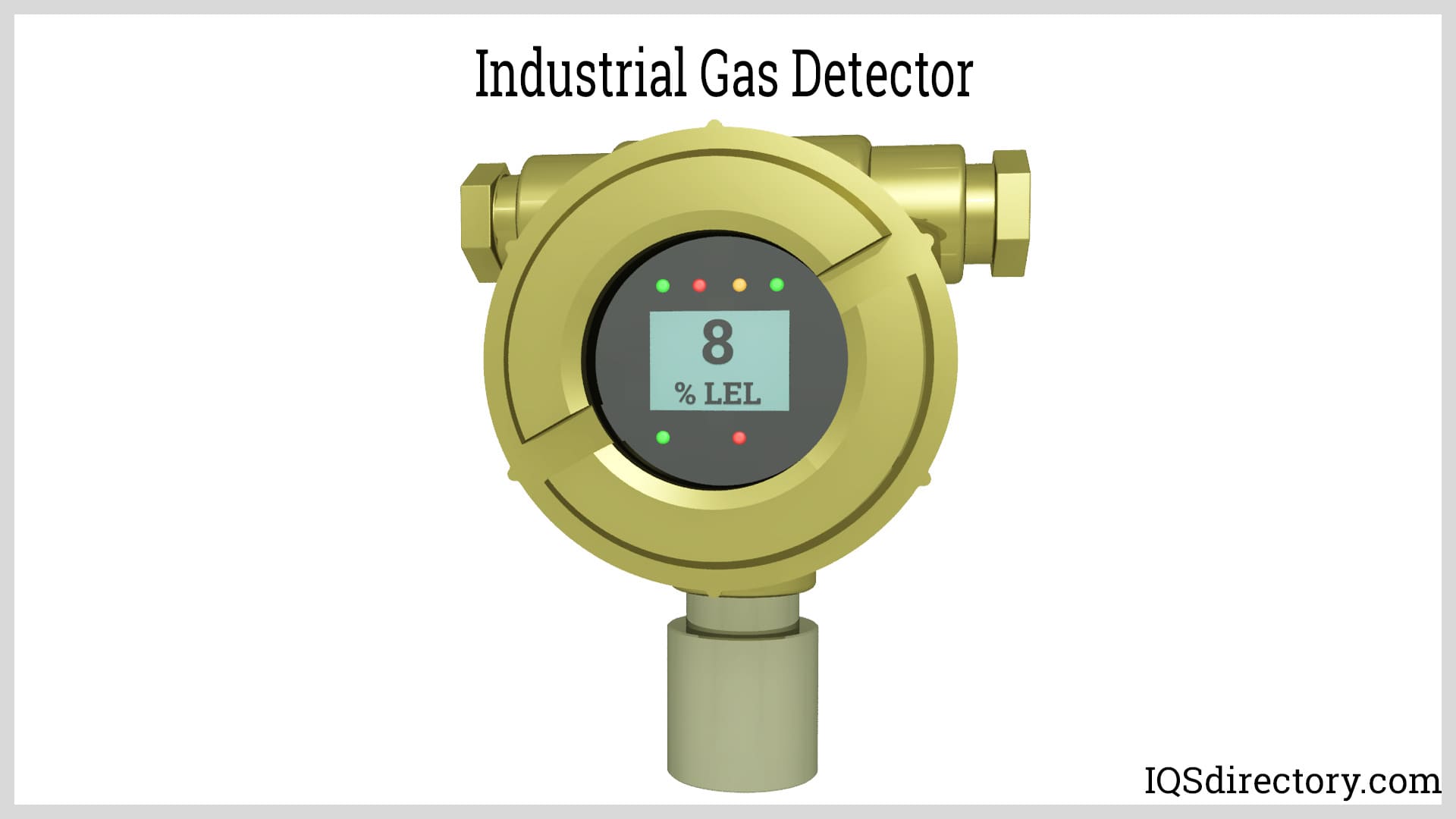

Electronic leak detectors are the most sensitive mechanisms of all the leak detectors and provide the fastest path to identifying and locating a gas leak. They are used more often than the other common leak detection systems, ultrasonic leak detectors, gas detectors and flame ionization leak detectors.

The electronic model can be programmed to identify a specific refrigerant or to include multiple possibilities. R12, R22 and R134a are among the most common refrigerants to be identified by electronic leak detectors, although R134a is more difficult to detect even with electronics. These numbers stand for three common gas leaks: helium, Freon and halogen.

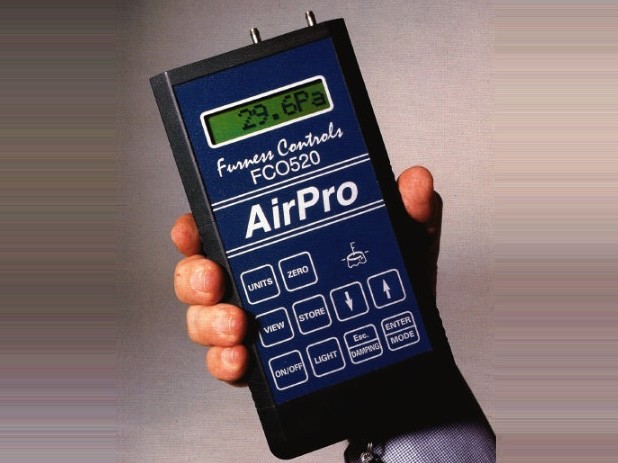

Many electronic leak detectors are handheld, to make it as easy and inexpensive as possible for owners of homes and businesses to make sure the air they breathe is safe. The danger of refrigerant gas leaks, to the health of individuals as well as to the equipment or furniture in the vicinity, can be devastating.

A vast variety of industries, including medical, industrial manufacturing, aerospace and automotive shops run the risk of leaks, not to mention any home or office with a central air system or refrigerator.

While nearly all types of leak detectors involve electronic components, heated diode and corona discharge are the two main types of electronic leak detectors. The most common electric run mechanism uses the corona discharge technology. A high voltage corona, or circle, is created in the sensing tip.

When entered into the field around the sensor, refrigerants break the corona barrier and trigger an alarm to notify the user of the leak. Despite their popularity, the major flaw of corona discharge leak detectors is that the corona barrier can be broken by other particles such as dust and moisture in the air, causing a false alarm.

The heated diode electronic leak detectors, although they function in much the same way, have fewer false positives because of the heated sensor. The heated sensors of this particular detector are triggered by absolute concentration, which causes alerts to increase as refrigerant amounts increase indicating proximity to the leak.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services