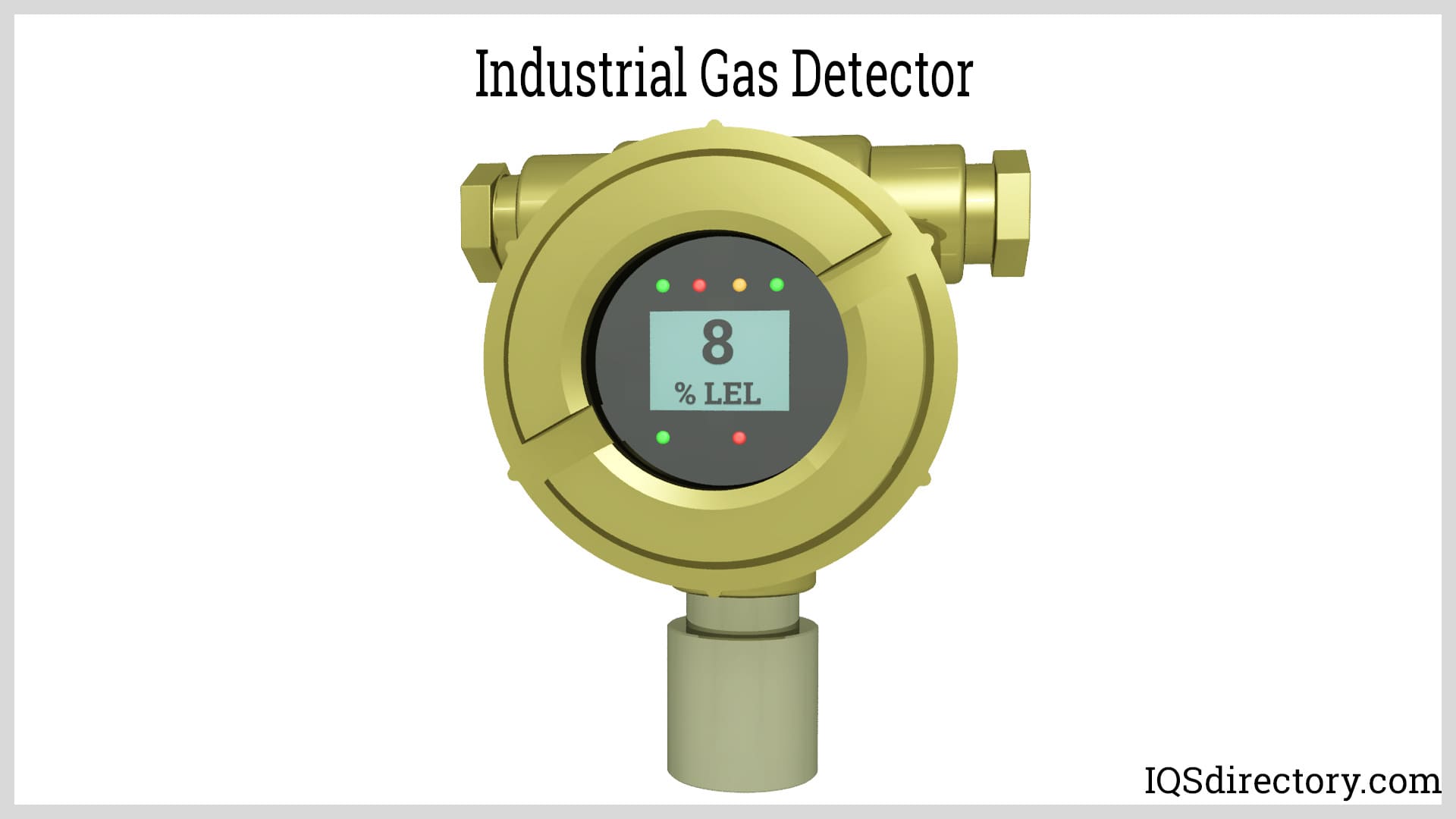

Leak detectors, also called gas detectors, per their application, detect, identify, and alert those in the area of gas or liquid system leaks. Using ultrasonic waves, sound, visible indicators, or flame ionization, leak detectors recognize changes in pressure and flow rates and can determine the size and composition of a leak. Many leak detectors are permanent members of a safety system, while others are temporary, detecting with portable sensors. Read More…

We are AMETEK MOCON, and we are dedicated to delivering advanced solutions for leak detection and package integrity testing. Our expertise lies in creating reliable instruments that help manufacturers ensure their products are protected, consistent, and safe.

At MSA, we dedicate ourselves to protecting lives by delivering products and technologies that safeguard workers in critical environments. We design and manufacture advanced safety solutions that give our customers confidence and peace of mind.

At UE Systems, we dedicate ourselves to advancing ultrasonic technology that helps our customers improve reliability, efficiency, and safety in their operations. We specialize in the development of leak detectors that allow facilities to identify and resolve issues in compressed air, gas, and vacuum systems before they become costly problems.

More Leak Detector Manufacturers

History of Leak Detectors

It may be surprising to modern sensibilities that early leak detection methods involved the literal sacrifice of living beings. During the Industrial Revolution and the rapid growth of the coal industry, detecting toxic methane gas became crucial for worker safety. Early gas leak detection systems were rudimentary—workers entered hazardous areas carrying a lighted torch and a wet blanket, risking their lives to check for dangerous methane buildup. Tragically, many of these workers fell victim to accidental combustion, highlighting the desperate need for safer detection technologies. The use of canaries in coal mines soon replaced these risky methods; canaries served as living gas leak alarms, responding to invisible methane gas by flapping violently or succumbing to the fumes, thus warning miners of impending danger.

As the demand for reliable gas leak detection expanded to other industries—including wastewater treatment, oil and gas refining, and industrial chemical processing—technological advancements emerged. Early gas monitors utilized catalytic diffusion to detect methane but required frequent manual calibration and maintenance. The 1920s saw groundbreaking innovations from Dr. Riken in Japan and the Standard Oil Company in the United States, who introduced leak detection equipment using light-wave interference and platinum catalysts to sense combustible gases. By the 1980s, solid-state semiconductor gas detectors revolutionized the industry, providing greater sensitivity, faster response times, and improved safety for a wide range of industrial and commercial applications.

Today, leak detector technology continues to evolve, integrating digital interfaces, wireless connectivity, and real-time data logging for comprehensive leak monitoring and reporting. Modern leak detection systems are essential for ensuring regulatory compliance, environmental stewardship, and the safety of personnel and property across diverse industry sectors.

Importance of Leak Detectors

Leak detectors play a vital role in protecting lives, property, and the environment by identifying hazardous gas and fluid leaks before they escalate into emergencies. The use of leak detection systems is especially critical given the broad spectrum of potentially dangerous gases and fluids present in residential, commercial, and industrial settings.

Natural gas is a primary energy source for water heaters, furnaces, stoves, and even vehicles. Composed mainly of methane, natural gas is highly flammable and colorless, with a high risk of explosion or fire in the event of an undetected leak. Because natural gas is odorless, utility companies add mercaptan, a sulfur-containing compound, to give it a distinctive smell for easier leak detection by humans. However, relying solely on the human sense of smell is insufficient, especially in large or complex facilities, making professional-grade gas leak detectors and gas detection systems an essential part of building safety protocols.

Beyond natural gas, refrigerant leaks pose significant risks to both health and the environment. Refrigerants, such as chlorofluorocarbons (CFCs) and hydrofluorocarbons (HFCs), are used in air conditioners, freezers, chillers, and refrigeration units. Leakage not only impairs equipment efficiency but can also lead to oxygen displacement, respiratory distress, and environmental hazards like ozone layer depletion and increased greenhouse gas emissions. Modern refrigerant leak detectors are designed to rapidly identify even trace amounts of escaping refrigerant, enabling fast repair and minimizing environmental impact.

Other hazardous gases, such as carbon monoxide (CO) and propane, are commonly found in residential and commercial settings. Carbon monoxide is a colorless, odorless gas resulting from incomplete combustion of fuels. CO exposure can be fatal, making carbon monoxide detectors mandatory in homes, hotels, and commercial buildings. Propane, used for heating and cooking, is heavier than air and can accumulate in low-lying areas, posing a severe fire and explosion risk. Proper leak detection for these gases is vital for occupant safety and regulatory compliance.

Are you looking for a comprehensive solution to safeguard your home, business, or industrial facility from hazardous gas leaks? Consider installing a state-of-the-art leak detection system tailored to your specific needs. What kind of gas leak detectors are best for residential vs. industrial settings? How do you choose between fixed gas detectors and portable leak detectors? Explore our expert guides and industry resources to find the right leak detection technology for your application.

Types of Leak Detectors

Leak detectors come in a wide variety of models, each designed for specific gases, applications, and environments. Understanding the main types of leak detectors will help you select the most effective gas or fluid leak detection technology for your needs.

By Installation: Fixed vs. Portable Leak Detectors

Fixed leak detectors are permanently installed in locations where continuous monitoring is required, such as industrial plants, mechanical rooms, SCADA-controlled facilities, and residential basements. These leak detection systems are often integrated with building automation systems, providing real-time alerts and automated safety responses (e.g., shutting off gas valves or activating ventilation systems).

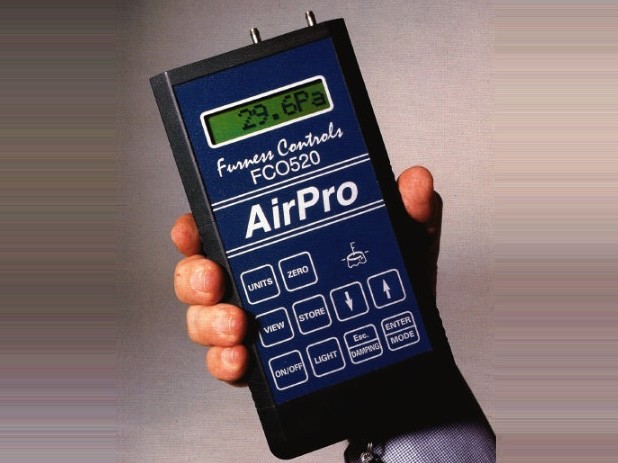

Portable leak detectors are battery-powered, handheld devices ideal for spot-checking or inspecting confined spaces, pipelines, and equipment. They are commonly used by maintenance staff, HVAC technicians, and safety inspectors to quickly identify the source of a suspected leak. Portable gas detectors and portable water leak detectors offer flexibility and convenience for on-the-go leak detection tasks.

By Target Substance: Combustible, Toxic, and Refrigerant Leak Detectors

Leak detectors are often categorized by the type of gas or fluid they are designed to sense:

- Combustible gas leak detectors: Detect flammable gases such as methane, propane, butane, and hydrogen.

- Toxic gas leak detectors: Sense hazardous gases like carbon monoxide (CO), hydrogen sulfide (H2S), ammonia (NH3), and chlorine.

- Refrigerant leak detectors: Specialized for halogenated refrigerants (CFCs, HCFCs, HFCs) used in HVAC/R systems.

- Water leak detectors: Designed to identify leaks from pipes, appliances, and infrastructure.

Choosing the right leak detector depends on the specific hazards present in your environment. Need help identifying which gases or fluids you should monitor? Read our leak detection guide for expert recommendations.

By Detection Technology: Methods and Sensors

The most effective way to classify leak detectors is by their detection method or the type of sensor technology they use. Each method offers unique advantages for different applications and environments:

- Gas leak detectors: These include a wide range of devices capable of detecting halogen, vacuum, freon, and natural gas leaks. How do gas leak detectors work? Most systems introduce a tracer gas—commonly hydrogen or helium—into the system. The detector, often paired with a mass spectrometer, measures the leak rate and pinpoints the leak location by quantifying the tracer gas concentration. Helium leak detectors are especially popular for their sensitivity, speed, and reliability. In mass spectrometer leak detection, helium is pumped into the test object, ionized, and measured as an electric current, providing a direct assessment of leak size and location.

- Electronic leak detectors: Renowned for fast detection and accuracy, these detectors primarily utilize either heated diode (semiconductor) or corona discharge technology. Heated diode detectors use a sensor heated to ionize gases, offering reliable detection in a wide humidity range and sensitivity to both combustible and toxic gases. Corona discharge detectors use a high-voltage tip to ionize gas molecules, triggering an alarm when a leak is detected. However, they are more susceptible to false alarms from moisture, solvents, or dust than semiconductor models.

- Ultrasonic leak detectors: These detect leaks by picking up high-frequency sound waves generated by gas escaping under pressure. The ultrasonic signals, typically inaudible to the human ear, are converted into audible sounds via headphones or speakers, allowing operators to locate leaks quickly. Ultrasonic leak detection is particularly effective for pressurized gas systems and industrial plant maintenance.

- Flame ionization leak detectors: These detectors use a small hydrogen flame between two electrodes to ionize organic compounds. The resulting ions produce a measurable current, which correlates directly with the concentration of leaking hydrocarbons. Flame ionization technology is widely used in environmental monitoring, petrochemical processing, and laboratory research.

- Infrared (IR) leak detectors: IR detectors sense combustible or toxic gases by transmitting infrared light across a sensing path and measuring absorption or interruption by specific gases. Infrared gas analyzers are ideal for detecting carbon dioxide, flammable hydrocarbon vapors, and refrigerants. Some models double as combustion analyzers, measuring both CO2 and flue gas composition for HVAC system efficiency.

- Leak testers and gas analyzers: These tools use differential pressure, vacuum decay, or flow measurement to detect leaks. While detectors identify abnormal concentrations, gas analyzers quantify specific gas amounts for process control, emissions monitoring, and product quality assurance.

Still unsure which leak detector technology is best for your application? Compare gas leak detectors, electronic leak detectors, and ultrasonic leak detectors side-by-side.

Water Leak Detectors

While gas leak detection has historically dominated the field, water leak detectors are now recognized as equally critical for residential, commercial, and industrial infrastructure. Water leaks can cause severe property damage, promote mold growth, and disrupt operations—making early leak detection essential for risk mitigation and cost savings.

Modern electronic water leak detectors use advanced acoustic sensors, known as transducers, to pick up sound waves generated by escaping water—even from tiny leaks deep within walls or underground pipes. These systems amplify and analyze signal frequencies, helping users accurately locate leaks and determine their severity. Water leak detectors are indispensable for detecting leaks in building plumbing, fire sprinkler systems, industrial water lines, oil pipelines, and steam systems.

Historically, water leak detection relied on acoustic listening devices and manual inspection. The invention of the topophone in 1879 significantly improved the ability to pinpoint sound sources in underground piping. Today, water leak detection technology has advanced to include thermal imaging cameras, infrared sensors, ground-penetrating radar (GPR), and networked leak monitoring systems that provide 24/7 water leak surveillance and real-time alerts.

Are you concerned about hidden water leaks in your property? What are the best water leak detection systems for homes and businesses? How can you prevent costly water damage and insurance claims? Learn more in our comprehensive water leak detector guide.

Leak Detector Applications

Leak detectors and leak testing instruments are essential across a broad range of industries, facilities, and use cases. Their versatility and high sensitivity make them invaluable for ensuring safety, efficiency, and compliance in diverse environments:

- Scientific and Automotive Manufacturing: Used for leak testing in water pumps, measuring equipment, cylinder heads, hydraulic systems, brake lines, radiators, and calibrated volume vessels; ensures product integrity and operational safety.

- Medical and Pharmaceutical: Critical for monitoring fluid transfer devices, medical gas delivery systems, sterile containers, laboratory pumps, and protective enclosures; helps prevent contamination and ensure patient safety.

- Automotive and Aerospace: Employed in quality control and end-of-line testing for vehicles, aircraft, and spacecraft components, including fuel tanks, HVAC systems, and pressurized cabins.

- Residential and Commercial Buildings: Used to detect carbon monoxide, natural gas, and water leaks in apartments, homes, hotels, and office spaces; supports occupant safety and reduces insurance risks.

- Industrial and Energy Facilities: Applied in welding shops, chemical plants, nuclear power plants, oil refineries, and gas pipelines to identify combustible and toxic gas leaks; vital for fire prevention and environmental compliance.

- Municipal and Utilities: Essential for monitoring water distribution networks, wastewater treatment plants, and sewer infrastructure; reduces non-revenue water losses and supports regulatory reporting.

Additional common water leak detector applications include:

- Basements and crawl spaces

- Areas at or below grade susceptible to water intrusion

- Floors near sump pumps and water heaters

- Under sinks, toilets, and dishwashers

- Behind washing machines and refrigerators with ice makers

- Near aquariums, fish tanks, and swimming pool equipment

- Inside attics beneath rooflines

- Hot tubs and spa enclosures

- Elevator pits and mechanical rooms

- Low points in commercial flooring and storage areas

Industrial leak detector use cases:

- Electric motor control centers

- Pump rooms and boiler rooms

- Food service and commercial kitchens

- Restrooms and laundry facilities

- Eye wash and safety stations

- Pharmaceutical manufacturing cleanrooms

- Data centers and server rooms (to protect critical electronics from water ingress)

Are you planning a leak detection project? Which leak detector is most effective for your facility type? How often should you test and calibrate your leak detection equipment? Find certified leak detector suppliers and service providers to ensure your system meets industry best practices.

Leak Detector Features, Benefits, and Buying Considerations

When evaluating leak detection equipment for purchase, consider the following features and benefits to ensure you select the best solution for your needs:

- Detection sensitivity and accuracy: High-quality detectors can sense even the smallest leaks, reducing false positives and missed leaks.

- Response time: Fast-responding detectors are critical for high-risk environments where rapid intervention can prevent disasters.

- Versatility and multi-gas capability: Some detectors can identify a wide range of gases or fluids, enhancing flexibility and return on investment.

- Portability and ease of use: Lightweight, ergonomic designs with intuitive interfaces improve usability for technicians and maintenance staff.

- Data logging and connectivity: Advanced models offer wireless connectivity, real-time monitoring, and integration with building management systems for comprehensive reporting.

- Power options: Consider whether the unit is mains powered, battery operated, or supports rechargeable batteries for continuous operation.

- Durability and ingress protection: Industrial-grade detectors should offer dust and moisture resistance (IP ratings), shock protection, and robust housings for harsh environments.

- Compliance and certification: Ensure your leak detector meets relevant industry standards, such as UL, CSA, ATEX, or IECEx for hazardous locations.

What are the most important factors to consider when selecting a leak detector? Are you looking for highly sensitive gas leak detectors, or do you need multi-channel water leak monitoring? Contact our experts for tailored recommendations and a free product demo.

Leak Detector Care and Upkeep

Proper maintenance and regular calibration are essential for ensuring the longevity and optimal performance of your leak detection equipment. Here are best practices for leak detector care:

- Inspect your leak detector before and after each use for physical damage, sensor integrity, and battery life.

- Clean the device regularly with a soft, damp cloth—avoid harsh chemicals or solvents that may damage sensitive components.

- Store the detector in a dry, temperature-controlled location, away from direct sunlight and corrosive substances.

- For battery-powered models, replace low batteries promptly and remove batteries if storing the detector for extended periods to prevent battery leakage and corrosion.

- Schedule periodic calibration and functional testing in accordance with manufacturer guidelines and regulatory requirements—calibration ensures detector sensitivity and accuracy remain within specified limits.

- Update firmware and software as recommended to maintain compatibility with new detection algorithms and system integrations.

- Train personnel on proper use, troubleshooting, and maintenance procedures to maximize the effectiveness of your leak detection program.

Want to maximize the lifespan and accuracy of your leak detectors? How often should leak detectors be calibrated? What are the signs that your leak detector needs servicing? Review our maintenance checklist or schedule a service appointment with a certified technician today.

Choosing the Right Leak Detector for Your Application

With so many options available—from simple electronic leak detectors to advanced multi-gas monitoring systems—selecting the ideal leak detection solution can be challenging. Here are key decision factors to guide your purchasing process:

- Type of substance to be detected: Identify whether you need a gas leak detector, refrigerant leak detector, or water leak detector based on your facility’s risk profile.

- Detection environment: Consider factors such as temperature extremes, humidity, airborne contaminants, and required measurement range.

- Required sensitivity and accuracy: Some applications, like cleanroom manufacturing or laboratory research, demand ultra-sensitive detection, while general facility monitoring may require broader detection thresholds.

- Integration requirements: Will your leak detector need to interface with alarms, building automation systems, or remote monitoring networks?

- Budget and total cost of ownership: Evaluate both initial purchase price and ongoing maintenance, calibration, and consumable costs.

- Regulatory compliance: Ensure your leak detection system meets or exceeds local, national, and industry-specific standards for safety and environmental protection.

Ready to improve your facility’s safety, efficiency, and environmental compliance with professional leak detection equipment? Request a quote, schedule a demo, or contact our leak detection experts to discuss your needs. Explore our directory of leak detector manufacturers and suppliers for the latest technologies and solutions.

What is the history of leak detectors and how did early systems work?

Early leak detection methods included risky practices such as miners entering hazardous areas with torches and wet blankets, and using canaries in coal mines as living alarms for toxic methane gas. Later innovations featured instruments based on catalytic diffusion, light-wave interference, and platinum catalysts, with significant advancements in the 1980s when solid-state semiconductor gas detectors provided greater sensitivity and safer monitoring.

Why are leak detectors important in both residential and industrial settings?

Leak detectors protect lives, property, and the environment by identifying hazardous gas and fluid leaks early, preventing emergencies such as explosions, fires, health hazards, or property damage. They are especially vital because many dangerous gases are colorless and odorless, making them difficult to detect without specialized equipment. Effective leak detection is a key part of regulatory compliance and overall safety protocols.

What types of leak detectors are available and how do they differ?

Leak detectors are available as fixed or portable devices and are categorized based on target substances (combustible gas, toxic gas, refrigerants, or water). Detection technologies include mass spectrometry, electronic heated diode, corona discharge, ultrasonic sensors, flame ionization, infrared sensors, and pressure or flow analysers. The selection depends on the type of hazard and monitoring needs.

How do gas leak detectors typically operate?

Gas leak detectors generally operate by sensing and measuring the presence of gases using various detection technologies such as introducing tracer gases (like helium or hydrogen), using mass spectrometry, ionizing gases with heated diodes or corona discharge, or analyzing infrared absorption. Some systems detect sound waves from gas escaping under pressure (ultrasonic), while others measure pressure changes or gas flow rates.

What are water leak detectors and how do they work?

Water leak detectors identify leaks in plumbing, appliances, or infrastructure. Modern electronic water leak detectors use acoustic sensors to pick up sound waves produced by escaping water, while advanced systems may employ thermal imaging, infrared sensors, or ground-penetrating radar. These technologies help locate leaks quickly, even if they are hidden behind walls or underground.

What features and factors should be considered when buying a leak detector?

Key factors include detection sensitivity and accuracy, response time, portability, multi-gas capability, data logging and connectivity, power options, durability, ingress protection (IP ratings), and compliance with industry standards. Buyers should also factor in ease of use, ongoing maintenance, and total cost of ownership.

How should leak detectors be maintained and how often should they be calibrated?

Leak detectors should be regularly inspected for damage, kept clean, stored properly, and have batteries checked or replaced as needed. Calibration and functional testing should be scheduled per the manufacturer’s guidelines and regulatory requirements to ensure sensitivity and accuracy remain within specifications. Software or firmware updates and staff training are also recommended for effective maintenance.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services