Leak Detection

Leak detection is a technique used to find leaks in industrial systems. The detection techniques can be internal or exterior, depending on where the leak detection system is installed. Leaks often escape when a metal container begins to suffer from corrosion. Leak detection offers an alternate way to test for corrosion damage. Read More…

DOD Technologies is committed to providing great service and customer care. From inquiry to delivery, our highly skilled team provides exceptional support and accountability to our customers. We offer Service Contracts, Calibration Services, Start Up Services, Field Service & Training and Installation & Design.

SERV-I-QUIP specializes in gas leak detectors, including helium leak detectors and halogen sniffer for air conditioning and refrigeration manufacturers. We also offer the leak test gas recycle system plus the proof, leak, flow test system. See us for your HVAC/R and appliance process equipment.

Vacuum Technology provides a variety of leak testing products including helium and refrigerant leak detectors. Our leak detectors offer quality of the highest industry standards for reliability and serviceability. We will custom design a leak detection system for you, so call us today!

ENMET, LLC is committed to providing gas detection solutions with quality products and services that conform to customer requirements. ENMET specializes in medical air, environmental and industrial health and safety monitoring instruments for a variety of hazardous gas conditions. ENMET’s focus is to provide innovative solutions utilizing sound engineering and quality manufacturing practices...

More Leak Detection Manufacturers

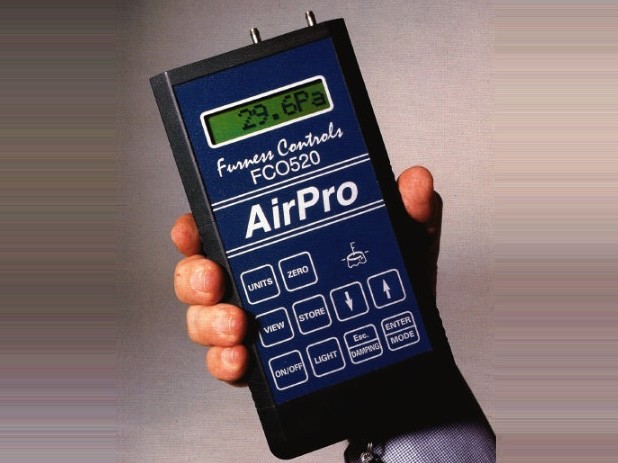

One can detect leaks manually with hand-held inspection tools. Automated technical leak detection systems continuously monitor system leaks and signal when leaks are found. Leak detection seeks to minimize, stop, and regulate accidental liquid or gas discharges.

Types of Leak detectors

Acoustic leak detector

The acoustic leak detector records the sound waves created by leaks and sends the leak's location to the safety control center. Leaks cause pipes under pressure to hiss, whoosh, splash, or thud with high-frequency sounds. Since each form of leak produces a different sound, the type of sound waves relies on their size, type of material, and type of leak. A highly sensitive transducer detects sound waves within an acoustic leak detector. A technician is informed that the sound's volume correlates directly with the pipe's pressure.

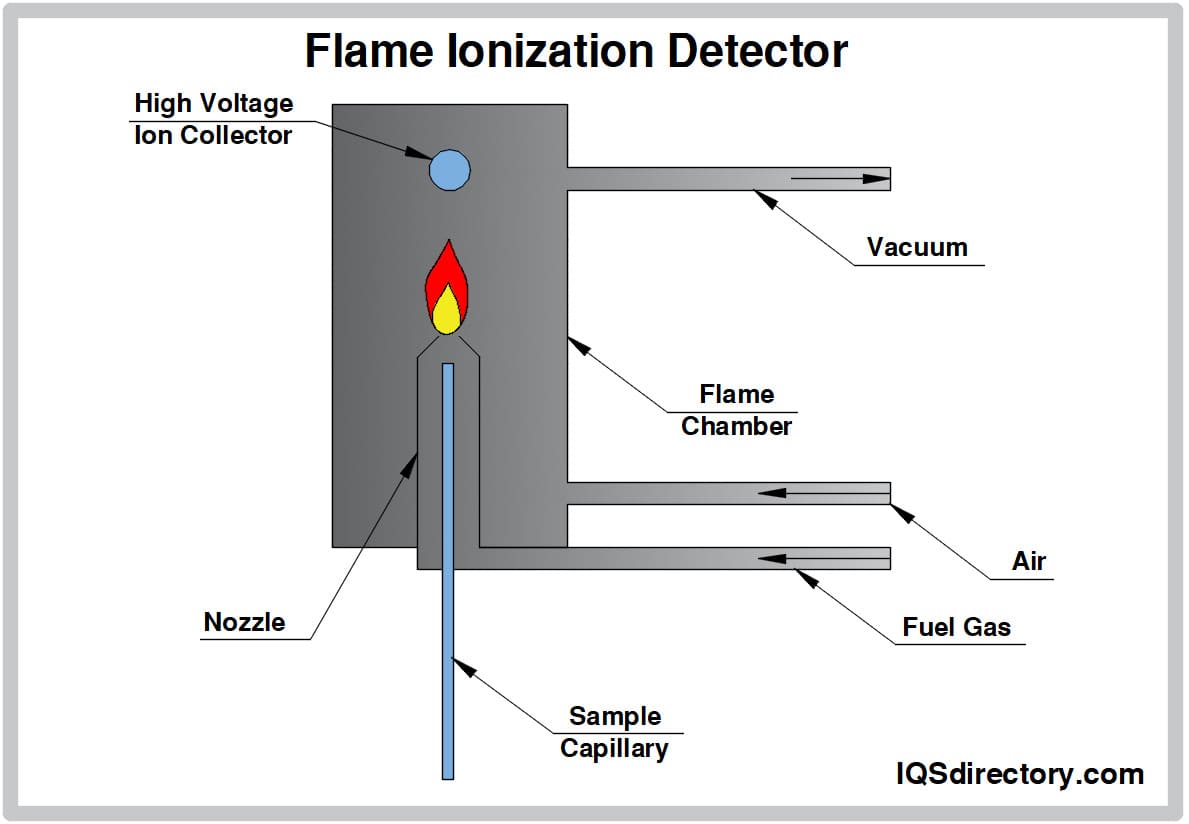

Flame Ionization Detector

A flame ionization detector comprises a hydrogen-air flame and a collection plate. As it travels through the flame, the effluent from the GC column breaks down organic molecules and creates ions. A biased electrode collects the ions, which then generate an electrical signal.

Fluorescent leak detection

Fluorescent leak detection is a quick and non-intrusive method for locating leaks in closed-loop systems using circulating fluid. The dye improves the search for leaks and helps determine whether the fluid being observed is an active leak in the system because it is made to be compatible with the existing hydraulic fluid and machine surfaces. The reservoir of the apparatus fills with a fluorescent dye, is mixed with the host fluid, and circulated through the system. A violet or ultraviolet flashlight initiates the luminous response after it has finished circulating. If there is a leak, the device will illuminate the leak when scanned.

Infrared Open Path Gas Leak Detection

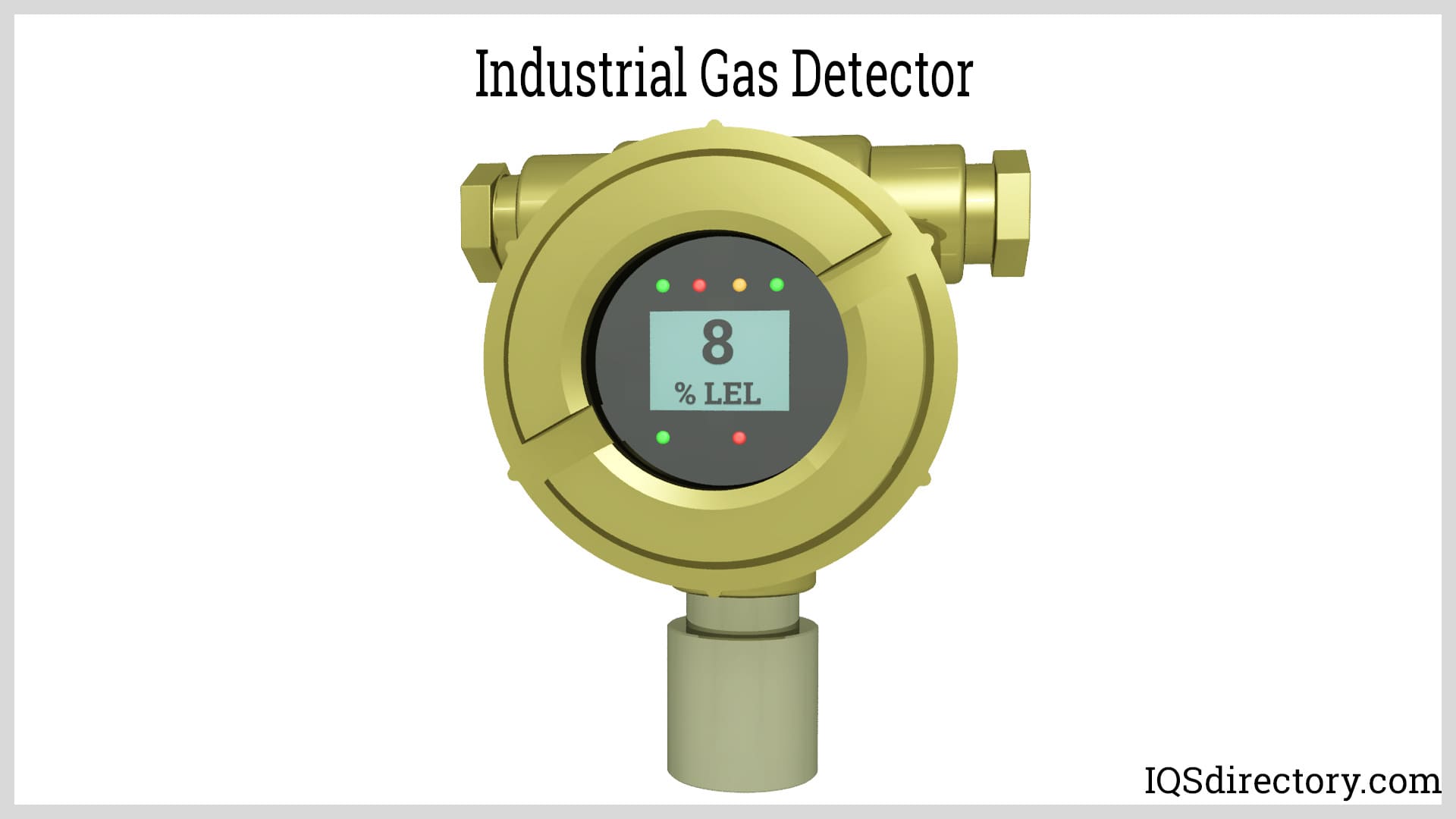

Infrared open path gas detectors absorb infrared light at particular wavelengths as the radiation travels through a gas. This helps determine the gas concentration of a leak. The detector consists of a light source and a light detector that measures the light's wavelength intensity. The wavelengths of active and reference absorption are measured by the two light sources. The discrepancy in wavelengths tells how much gas is present.

High Voltage Leak Detection

High voltage leak detection is a high-speed pinhole or dielectric flaw detection approach for components built-in high-speed production. The test item is sandwiched between two electrodes. While one electrode is grounded, the other electrode has a higher voltage. If the substance under test is solid, no voltage will flow from the elevated electrode to the grounded electrode, indicating that the item is flawless.

Applications for Leak detectors

- Hydraulics: Most leaks in a hydraulic system are visible externally, so most leak detectors are used for internal leak detection where visibility is infringed.

- Food packaging: Used to make sure food products are airtight.

- Air conditioning: Leaks in air conditioners cause refrigerant leaks that can harm the compressor.

Advantages of leak detection

- Loss Prevention: Environmental protection is the main concern for leaks. However, it’s also important to consider profit loss. Manufacturers may lose profitable resources through unmonitored leakage. Companies can reduce asset losses with an effective, dependable leak detection system.

- Labor reduction: Modern leak detection devices have the added benefit of preventing the need for digging and searching by identifying, localizing, and mapping the position of a leak before it becomes obvious. As a result, a leak is found and fixed with little harm.

- No interference: The operation of a facility is not impacted by leak-detecting equipment. They are positioned in strategic locations where they can offer the most quantity of data. Their installation serves the primary purpose of safeguarding employees and resources without interfering with productive activity.

Choosing the Right Leak Detection Company

To ensure the most positive outcome when selecting a leak detection company, it is important to compare several businesses using our directory of leak detection companies. Each leak detection company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the business for more information or request a quote. Review each leak detection business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple leak detection businesses with the same form.

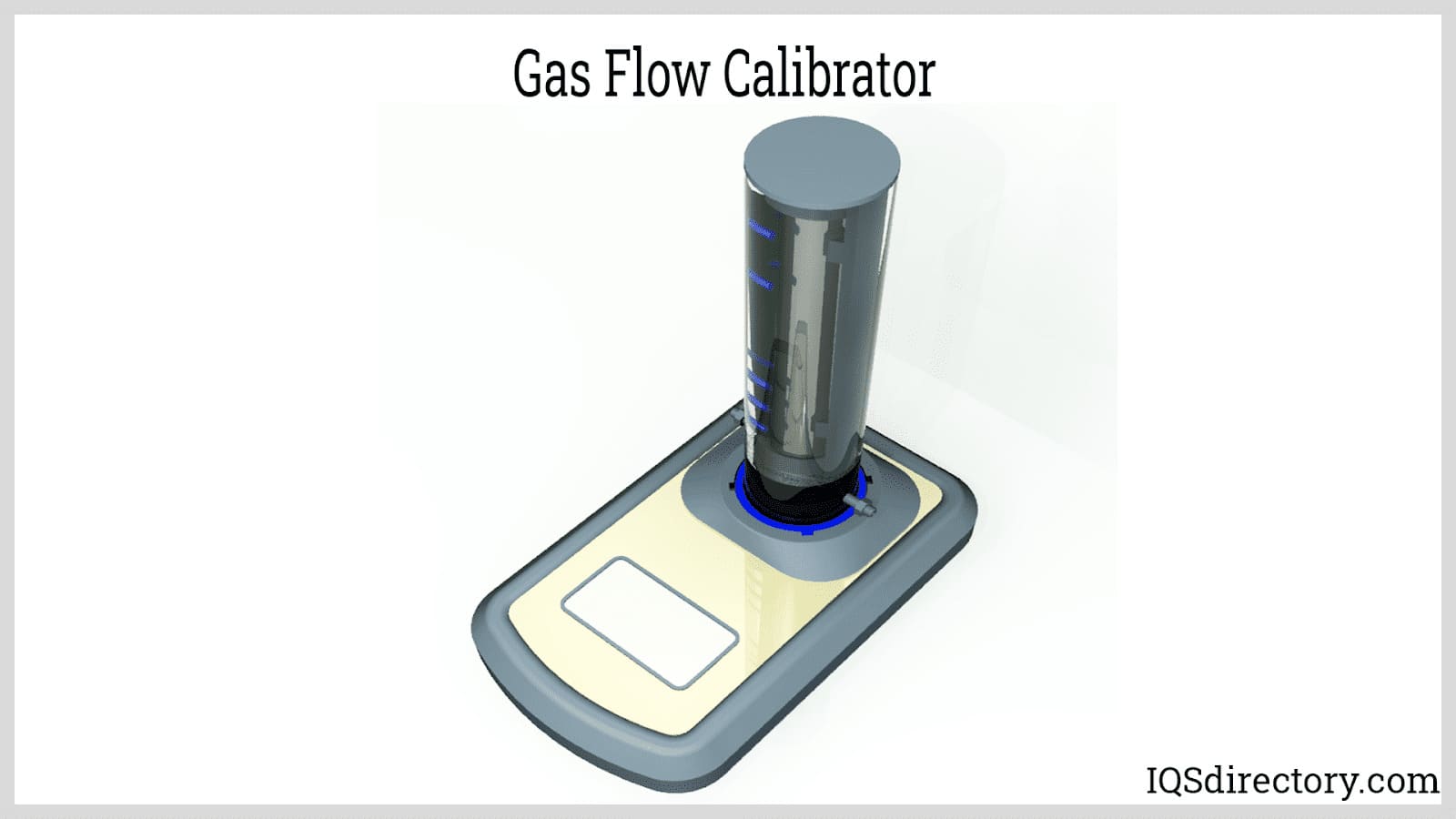

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services