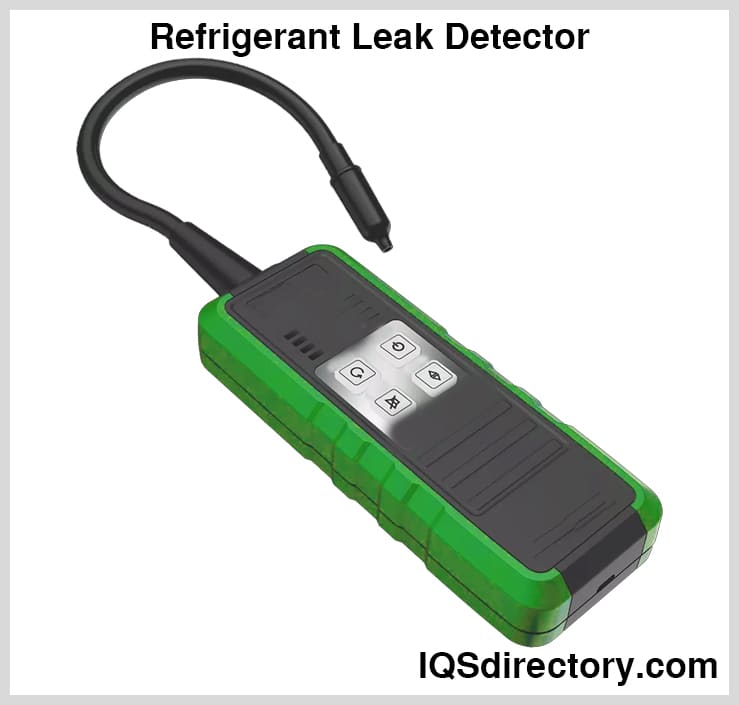

Effective refrigerant leak detection is essential to maintain safety, establish compliance, and increase energy efficiency. Finding leaks in refrigerants can be done with electronic leak detectors. An HVAC system will inevitably have refrigerant leaks when there are incorrectly fitted or welded joints. Some leaks are minor, amounting to only one ounce over ten years without inhibiting the system’s functionality. However, extreme temperatures, surroundings, and vibrations can exacerbate small leaks. If these flaws aren’t fixed, they’ll reduce the efficiency of the HVAC system. Read More…

DOD Technologies is committed to providing great service and customer care. From inquiry to delivery, our highly skilled team provides exceptional support and accountability to our customers. We offer Service Contracts, Calibration Services, Start Up Services, Field Service & Training and Installation & Design.

SERV-I-QUIP specializes in gas leak detectors, including helium leak detectors and halogen sniffer for air conditioning and refrigeration manufacturers. We also offer the leak test gas recycle system plus the proof, leak, flow test system. See us for your HVAC/R and appliance process equipment.

Vacuum Technology provides a variety of leak testing products including helium and refrigerant leak detectors. Our leak detectors offer quality of the highest industry standards for reliability and serviceability. We will custom design a leak detection system for you, so call us today!

ENMET, LLC is committed to providing gas detection solutions with quality products and services that conform to customer requirements. ENMET specializes in medical air, environmental and industrial health and safety monitoring instruments for a variety of hazardous gas conditions. ENMET’s focus is to provide innovative solutions utilizing sound engineering and quality manufacturing practices...

More Refrigerant Leak Detector Manufacturers

How to Find a Refrigerant Leak

There are many ways to find refrigerant leaks, but the most common methods include the following:

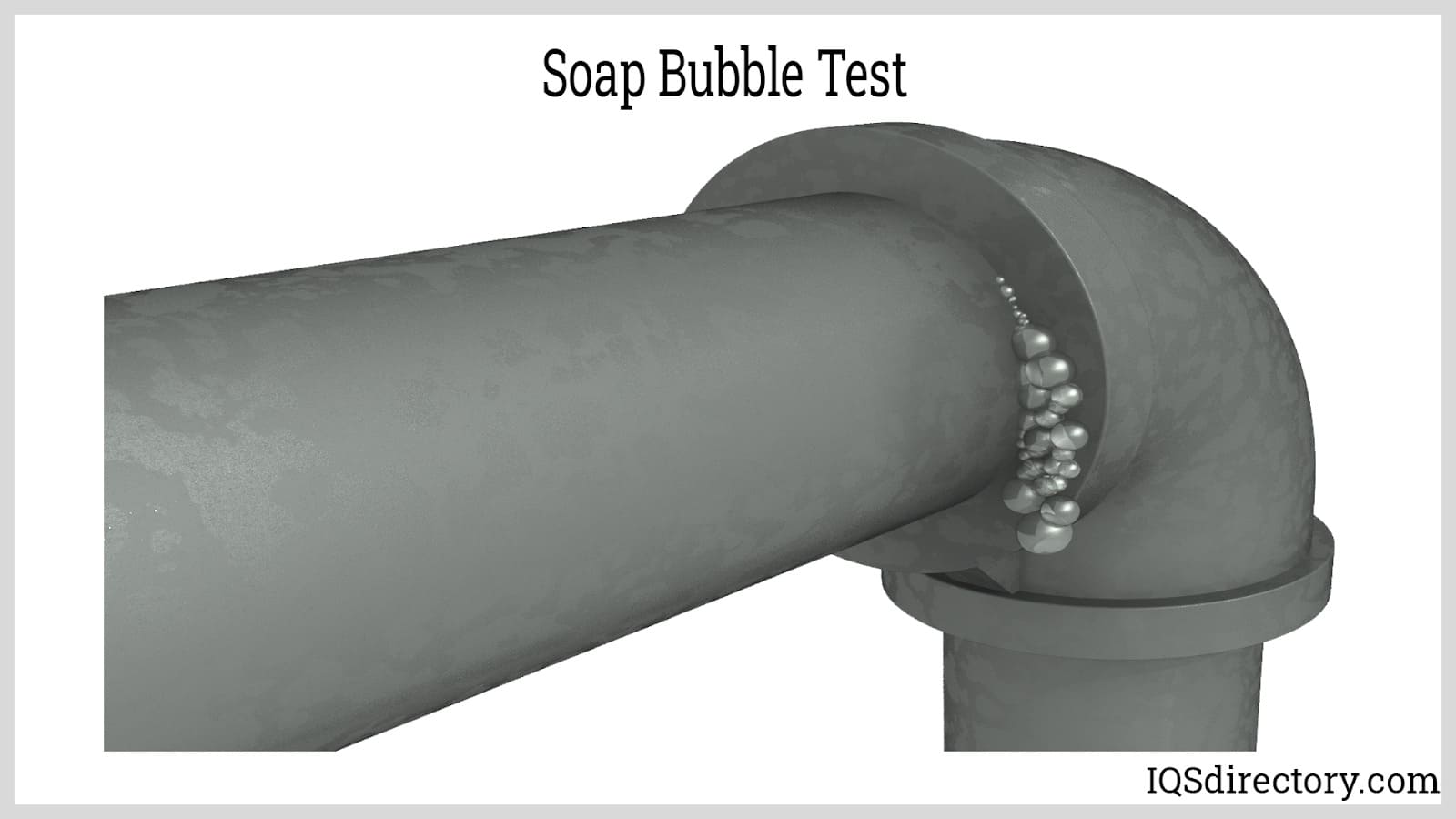

- Soap bubble method: Many technicians depend on the soap bubble approach. Spray a leak detection fluid or apply soapy water to check for leaks at specific spots. Leakage sites should start to produce bubbles. The soap bubbles approach is ineffective for minor leaks or windy environments. It’s more effective to pair the soap bubble approach with an electronic leak detection method.

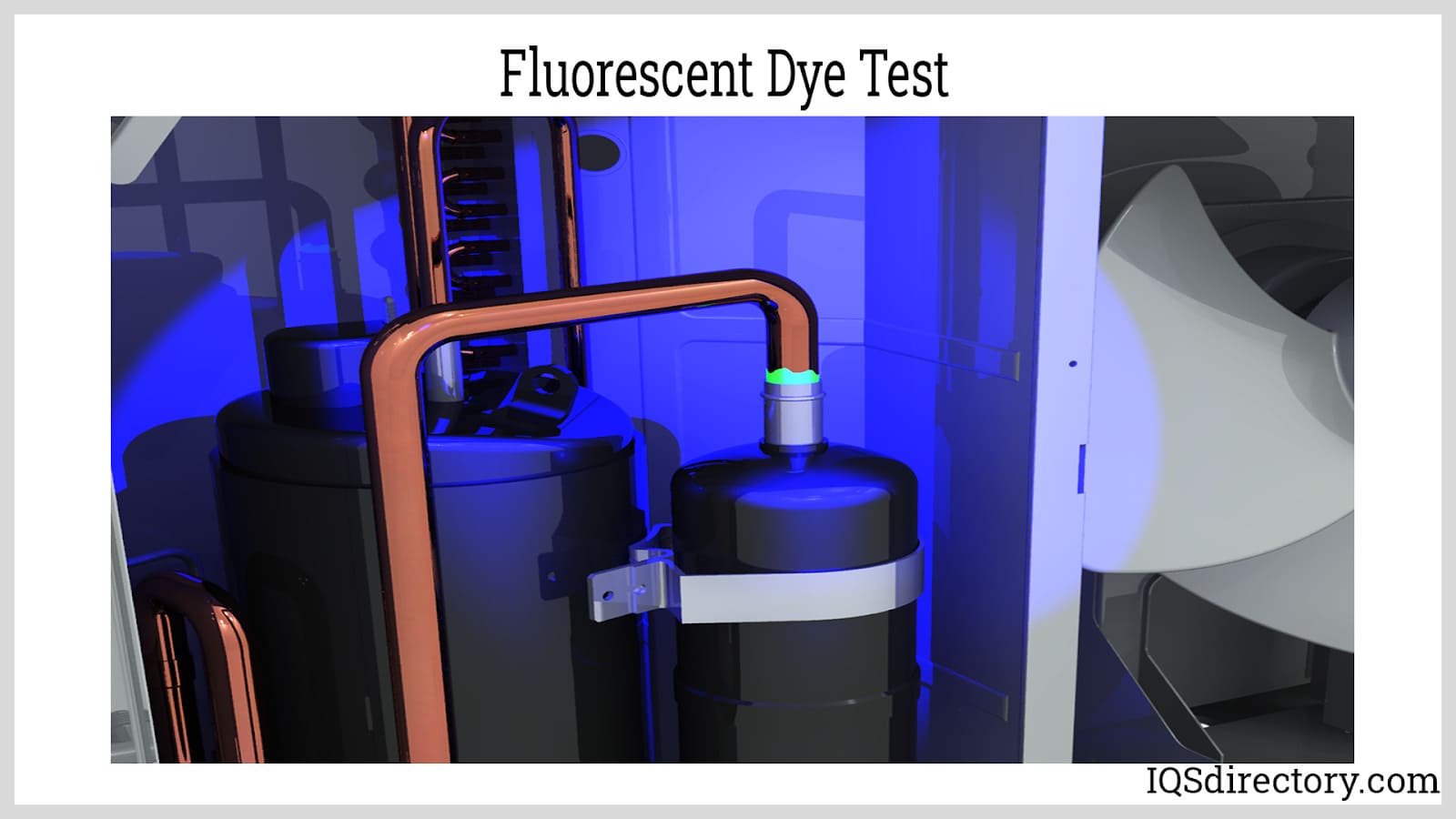

- Fluorescent dye method: The refrigerant is mixed with a fluorescent dye, then introduced into the refrigeration system. The dye will escape from the system and gather at any leak spots. Afterward, these leak locations will immediately be visible under a UV lamp. The fluorescent dye approach has a significant drawback; it may hurt the long-term functionality of HVAC-R systems.

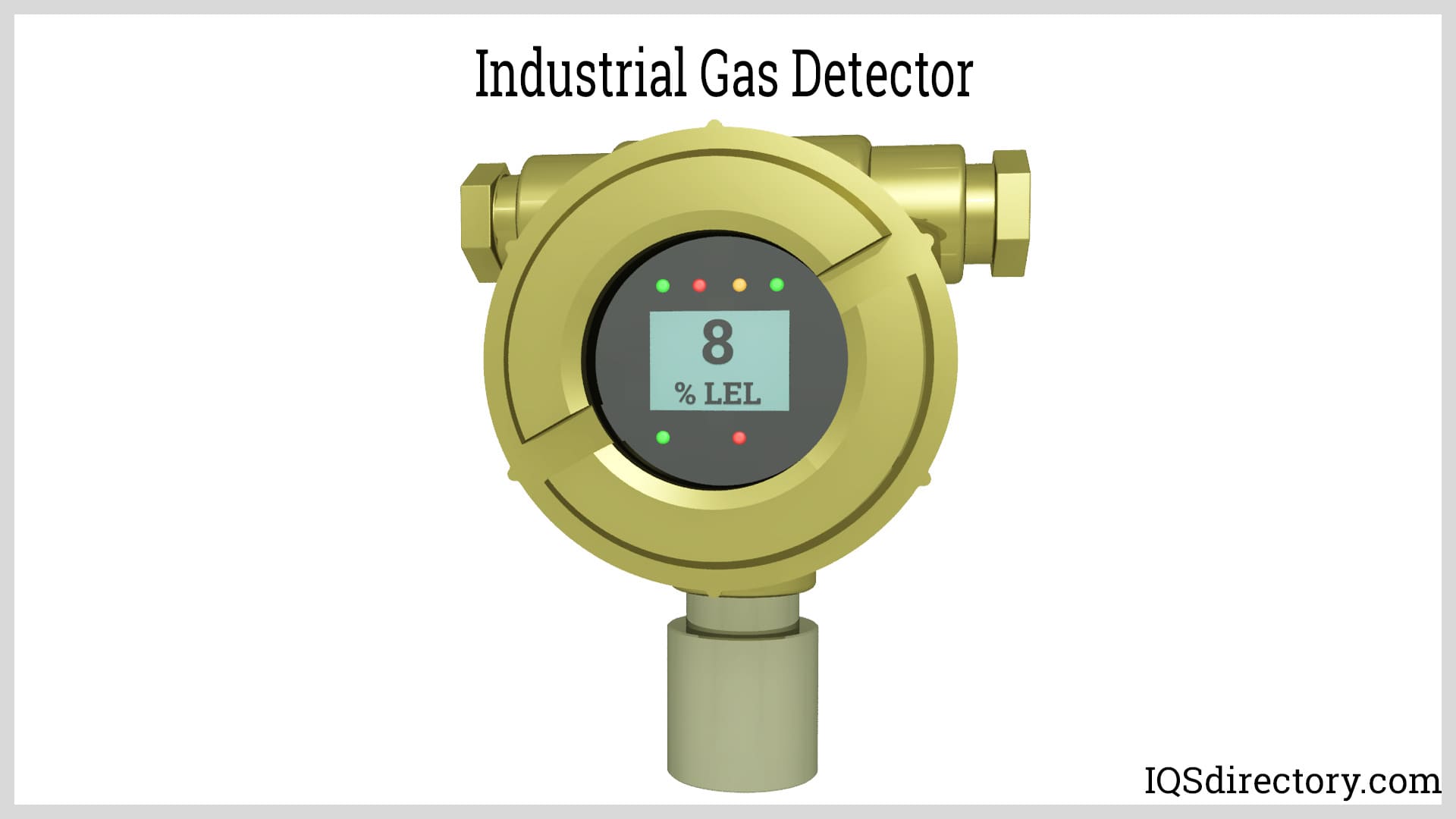

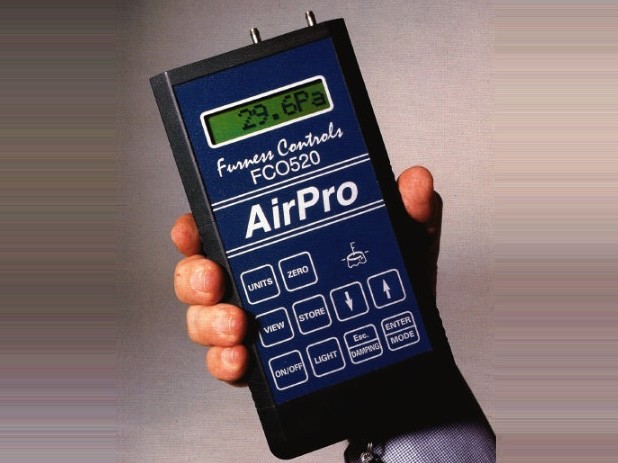

- Electronic leak method: The electronic leak method is the most accurate, effective technique. Electronic leak methods include corona-suppression, heated diode, infrared, and ultrasonic leak technologies.

- Corona suppression: Corona suppression involves a current flowing between two electrodes inside a device. There is a known baseline for this current. When a refrigerant gas enters the device and passes across the electrodes, the current drops below the baseline. The drop in current signals a gas presence and activates an alert. This method may be prone to false alerts.

- Heated diode: In heated diode leak detection, a refrigerant is heated until the molecules are dispersed. Chlorine or fluorine, chemical components present in most refrigerants, are positively charged quantities due to this reaction. Electronic refrigerant detectors use heated diode technology to detect chlorine or fluorine ions and sound an auditory alert to indicate a leak. Compared to corona suppression, this method is less likely to cause false alarms.

- Infrared: A method known as infrared leak detection uses infrared light to find refrigerants. Some infrared light is absorbed by the refrigerant, and the amount of the refrigerant concentration change is measured. This technology is delicate and precise.

- Ultrasonic: Ultrasonic leak detection identifies the sounds of escaping gasses like refrigerants. When an HVAC-R device leaks refrigerant, it creates an ultrasonic noise that’s inaudible to the human ear. However, the pressure will trigger a response from an ultrasonic detector.

- Halide leak detector: This is the most common method of identifying refrigerants containing chlorine. Currently, this approach can be used to identify CFCs and HCFCs but not HFCs. Halide leak detectors have a sample tube, a flame-powered end, and a propane or acetylene gas-powered end. The gas leak will be drawn to the sample tube by the draft the propane creates. The flame then changes color as it passes across a heated copper element. Therefore, inspecting it in direct sunlight is less efficient. If larger amounts of methyl chloride are present, the flame will turn green and blue.

Effectiveness of The Leak Detection Methods

- Soap bubble method: Effective for locating leaks but can be hampered by tiny leaks or windy conditions.

- Fluorescent dye: can be untidy, negatively impact system performance, and shorten the system lifespan of refrigerators.

- Electronic leak detectors: Very sensitive and effective for discovering the majority of leaks if used and maintained properly.

Choosing the Correct Refrigerant Leak Detector Supplier

To ensure you have the most productive outcome when purchasing a refrigerant leak detector from a refrigerant leak detector supplier, it is important to compare several companies using our directory of refrigerant leak detector suppliers. Each refrigerant leak detector supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each refrigerant leak detector business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple refrigerant leak detector companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services