Both the pump and flame methods can give false results depending upon environmental contaminants near the test. Advancements in either technique constantly decrease the room for false positives. Read More…

DOD Technologies is committed to providing great service and customer care. From inquiry to delivery, our highly skilled team provides exceptional support and accountability to our customers. We offer Service Contracts, Calibration Services, Start Up Services, Field Service & Training and Installation & Design.

SERV-I-QUIP specializes in gas leak detectors, including helium leak detectors and halogen sniffer for air conditioning and refrigeration manufacturers. We also offer the leak test gas recycle system plus the proof, leak, flow test system. See us for your HVAC/R and appliance process equipment.

Vacuum Technology provides a variety of leak testing products including helium and refrigerant leak detectors. Our leak detectors offer quality of the highest industry standards for reliability and serviceability. We will custom design a leak detection system for you, so call us today!

ENMET, LLC is committed to providing gas detection solutions with quality products and services that conform to customer requirements. ENMET specializes in medical air, environmental and industrial health and safety monitoring instruments for a variety of hazardous gas conditions. ENMET’s focus is to provide innovative solutions utilizing sound engineering and quality manufacturing practices...

More Halogen Leak Detector Manufacturers

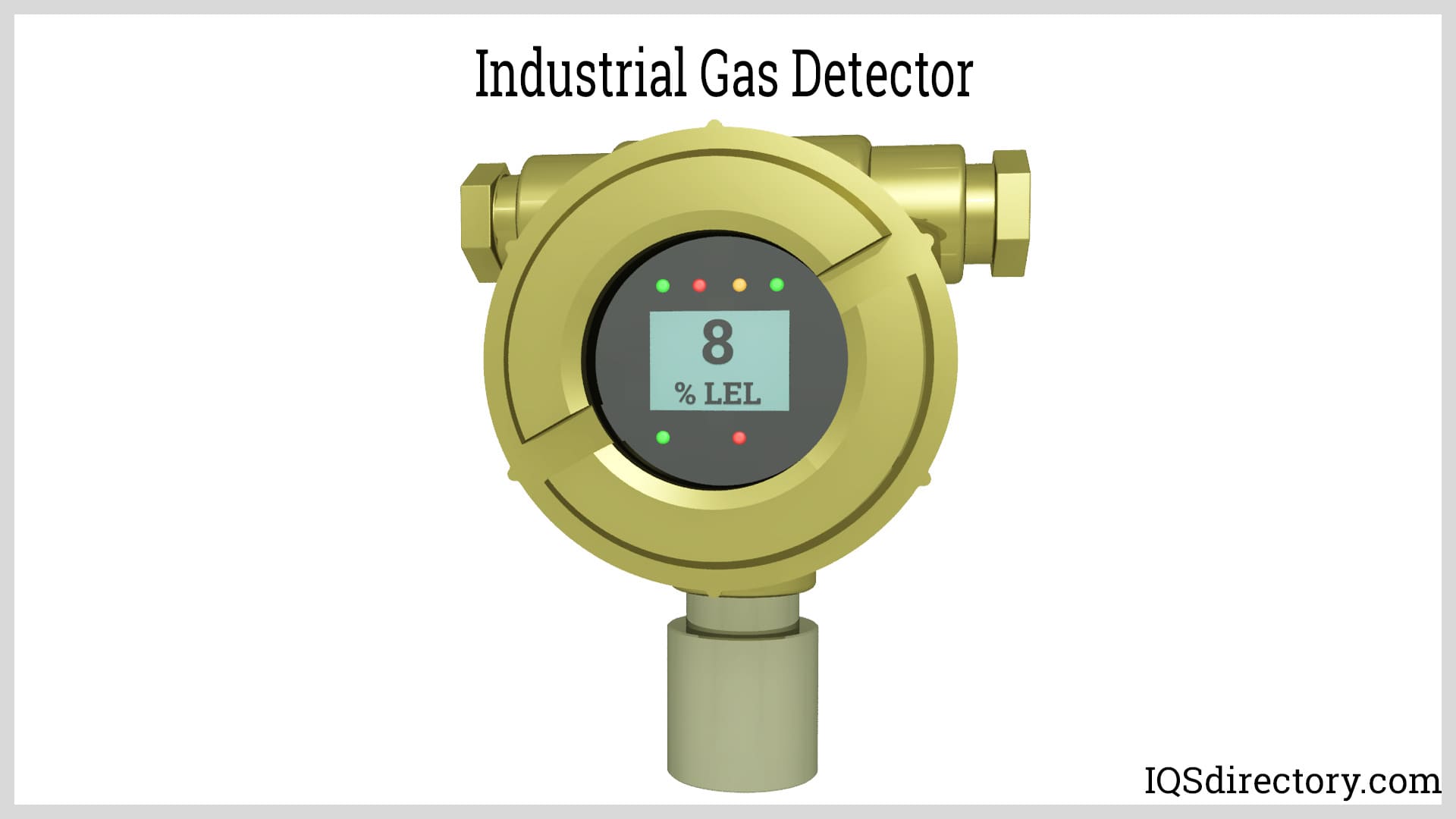

Gases containing halogen, such as chlorofluorocarbon and hydrofluorocarbon, are common in industrial, automotive and commercial cooling systems. The majority of halogen leak detectors use an automatic pump to sample the air surrounding the equipment, as do many leak detectors, such as Freon leak detectors and vacuum leak detectors.

Some leak detector systems, like one that identifies helium leaks, can be automatic, semi-automatic or manual. No matter how the detector runs, the point remains that its purpose is to detect gases and identify the precise location of a leak. Once detected, the air is drawn through a metal or plastic tube and compared to preset samples.

These pumps are calibrated to different types of halogenated gases and can often be customized to fit the exact needs of a given appliance. One other testing variation involves a halide torch test. The flame, which is normally blue, changes to a greenish hue when the presence of a halogen is detected.

Refrigeration and cooling systems often contain hundreds of feet of tubing, particularly in industrial settings. Even in smaller systems the tubing that must be monitored for leaks is commonly in inaccessible sections of the equipment. The area where the tubing resides could also still be running while the tests are being conducted.

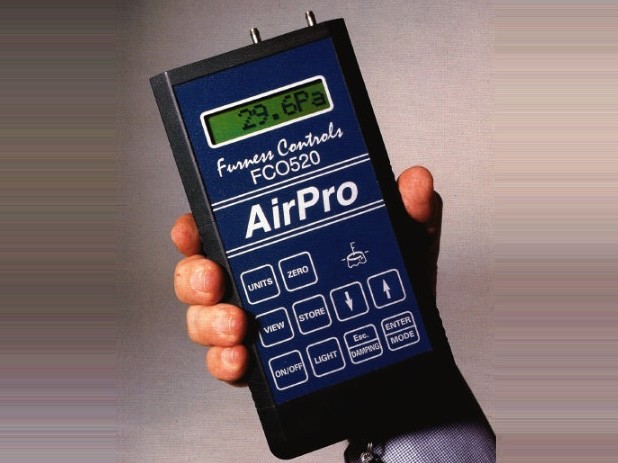

Nevertheless, identifying leaks is essential to these systems, since leaks can significantly decrease machine and system performance. If left unchecked, leaks can lead to appliance failure. For this reason many of the most popular halogen leak detectors are hand held and extremely portable. Hand held pump devices have two main parts, the body and the tubing. The tube is often made of bendable metal or plastic to fit into specific locations.

The body can be metal or plastic and houses the battery and testing components. Despite the benefits of portability, some large cooling and refrigeration systems may be continuously monitored with a fixed halogen leak detector. In some regions, constant monitoring is required as halogenated refrigerants increase ozone depletion. Although most halogenated refrigerants are not harmful to humans in small doses, large amounts can aggravate heart problems.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services